Comprehending Gauge Fillet Weld: A Comprehensive Overview for Welders

Comprehending Gauge Fillet Weld: A Comprehensive Overview for Welders

Blog Article

Innovative Techniques to Fillet Weld Examination and Screening: Enhancing Weld Top Quality and Conformity Specifications

In the realm of welding, the quality and honesty of fillet welds play a vital role in guaranteeing the structural stability and dependability of different industrial components. With the consistent drive for improved efficiency and conformity with rigid requirements, the exploration of cutting-edge strategies to fillet weld inspection and screening has actually become imperative.

Advanced Non-Destructive Testing Techniques

Using state-of-the-art technologies, advanced non-destructive testing approaches play a vital duty in making sure the integrity and quality of fillet welds. These techniques, such as phased selection ultrasonic screening (PAUT) and magnetic fragment screening (MPT), offer comprehensive understandings right into the weld's interior framework without causing any type of damage to the product. PAUT, as an example, makes use of numerous ultrasonic components to inspect the weld from various angles, offering an extensive visualization of prospective problems like lack of fusion or splits.

By using these sophisticated non-destructive testing methods, weld inspectors can properly evaluate the top quality of fillet welds, making sure compliance with market standards and guidelines. The ability to find defects early on not just improves weld high quality however also stops costly rework or failures in architectural integrity, highlighting the significance of these ingenious screening methods in welding examinations.

Robotics and Automation in Assessment

The integration of robotics and automation has reinvented the examination process for fillet welds, improving performance and accuracy in quality assessment. Robotics supply specific control and repeatability in examining welds, making sure trustworthy and consistent results. Automated systems can be programmed to comply with certain examination paths, ensuring extensive insurance coverage of welds and lowering the danger of human mistake.

Robot examination systems furnished with advanced sensing units can find and determine weld attributes with high accuracy, providing thorough data for evaluation. These systems can determine problems such as splits, absence of combination, and porosity, enabling punctual corrective actions to be taken. Additionally, robotics and automation permit real-time data collection and analysis, giving instant responses to operators and facilitating fast decision-making procedures.

Moreover, the usage of robotics and automation in fillet weld evaluation boosts general performance by decreasing evaluation times and increasing assessment throughput. By simplifying the evaluation procedure, manufacturers can guarantee weld top quality and compliance requirements are satisfied successfully, inevitably resulting in cost financial savings and improved item high quality.

Making Use Of Artificial Intelligence for Analysis

Expert system plays a crucial duty in enhancing the effectiveness and accuracy of analysis in fillet weld evaluation processes. By taking advantage of the power of AI, assessors can simplify the evaluation of weld top quality and conformity requirements, causing extra specific and dependable outcomes. AI formulas can quickly process large amounts of information from weld examinations, detecting defects or disparities that may be challenging to relate to the nude eye. This innovative technology enables real-time monitoring of weld top quality, permitting immediate corrective actions to be taken if any kind of problems are identified.

In addition, AI systems can gain from previous assessment information, continually enhancing their ability to determine potential flaws and discrepancies in fillet welds. This flexible learning ability boosts the general top quality control process, lowering the probability of human error and ensuring that welds satisfy the called for standards. By incorporating expert system right into fillet weld evaluation, markets can attain higher levels of effectiveness, uniformity, and conformity in their inspection methods.

Portable Devices for On-Site Inspection

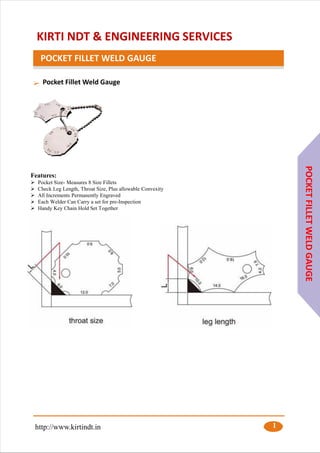

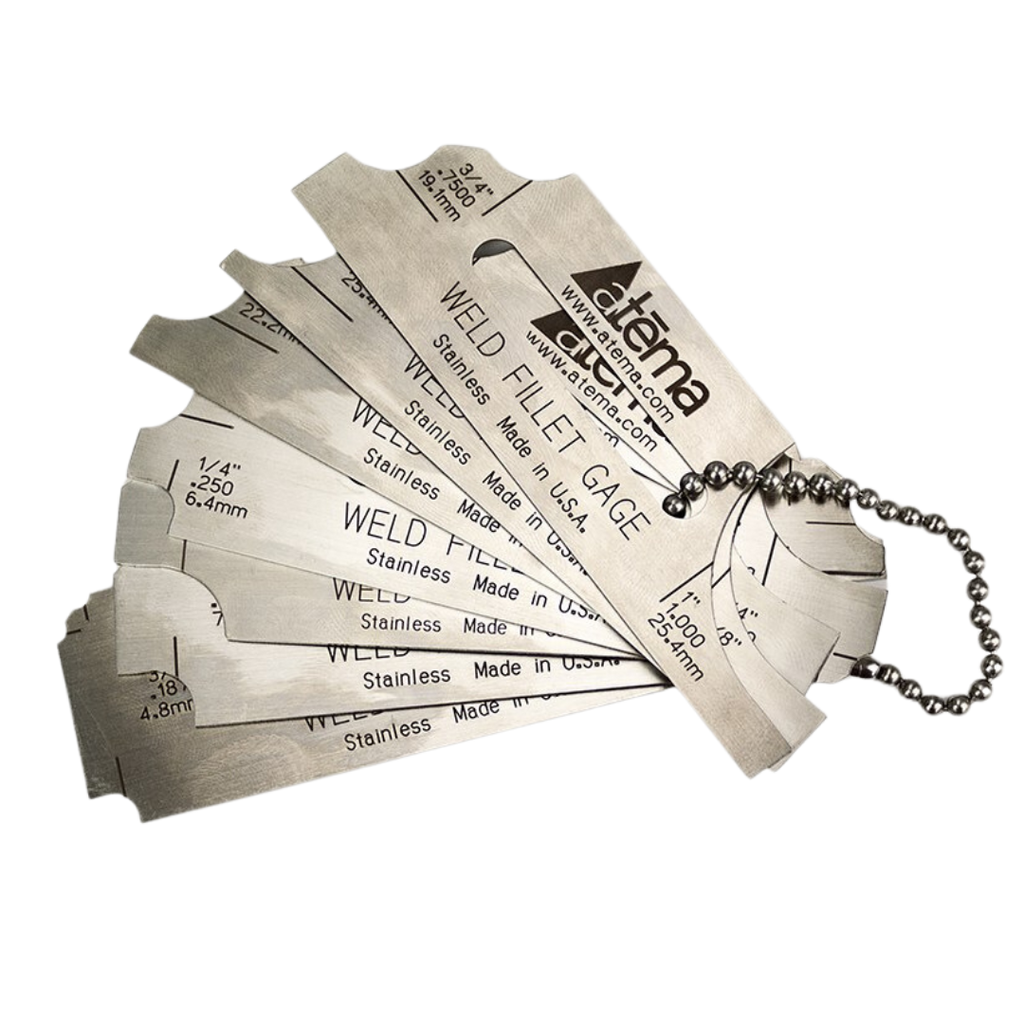

Enhancing field assessment performance, the adoption of portable tools changes on-site assessment processes for fillet welds. These tools use versatility and ease, allowing inspectors to conduct complete exams in numerous areas, consisting of remote or challenging environments. Portable tools such as ultrasonic testing devices, magnetic fragment examination equipment, and digital radiography systems offer real-time data and high-resolution imaging capabilities, allowing quick decision-making and immediate feedback on weld top quality.

One substantial benefit of mobile devices is their capability to improve assessment treatments, lowering click for source downtime and boosting general efficiency - Gauge Fillet Weld. Inspectors can easily deliver these devices to various task sites, eliminating the demand for moving hefty machinery or components to off-site centers. Furthermore, the mobility of these devices promotes cost-effectiveness by minimizing transport costs and accelerating examination timelines

In addition, making use of portable devices for on-site evaluation advertises positive quality control actions, as examiners can quickly recognize i was reading this and attend to any possible welding defects or disparities. By integrating these cutting-edge innovations right into on-site assessment practices, welding specialists can guarantee conformity with industry requirements and boost weld high quality, inevitably causing boosted structural integrity and safety and security in various welding applications.

Combination of Information Administration Equipment

Having enhanced on-site inspection procedures through the application of mobile tools, the next stage includes the smooth assimilation of data administration systems to further improve performance and data analysis abilities in fillet weld inspection and testing. By incorporating information management systems into the examination procedure, organizations can enhance information collection, storage space, and analysis. This combination permits for real-time monitoring of weld high quality, instant identification of issues, and prompt decision-making to correct any type of problems that might occur throughout the examination procedure.

Information management systems play an important duty in streamlining assessment information, helping with easy gain access to for licensed workers, and making sure data stability and safety. Through the combination of these systems, assessors can generate comprehensive records, track historic data for Get More Information fad evaluation, and enhance overall procedure performance. The assimilation of information monitoring systems makes it possible for seamless interaction between various stakeholders entailed in the examination process, promoting partnership and enhancing overall top quality control procedures. Inevitably, the integration of data management systems serves to boost the standards of fillet weld evaluation and screening, making certain compliance with market policies and boosting weld quality.

Verdict

In conclusion, ingenious techniques to fillet weld inspection and testing have considerably boosted weld quality and compliance criteria. Advanced non-destructive screening techniques, robotics, automation, synthetic intelligence, portable devices, and information administration systems have actually changed the way weld examinations are carried out. By making use of these technologies, sectors can guarantee that welds satisfy the needed top quality requirements and regulations, eventually improving total efficiency and safety and security in welding processes.

Having maximized on-site inspection procedures through the application of mobile devices, the next stage includes the smooth combination of data management systems to additionally enhance effectiveness and information evaluation capabilities in fillet weld examination and screening. Ultimately, the assimilation of data administration systems offers to raise the standards of fillet weld examination and screening, making certain conformity with industry regulations and boosting weld high quality.

Report this page